Printing Formats

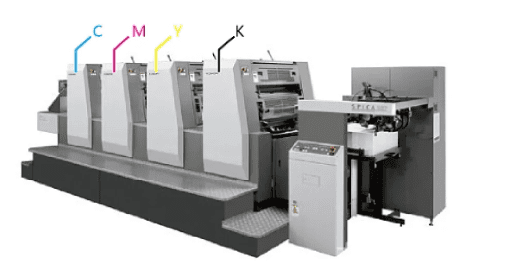

There are two prevalent printing formats in use today: traditional offset printing and digital printing.

Traditional Offset Printing

The workflow of traditional offset printing involves plate production (utilizing four-color plates) with the application of dampening solution and ink onto the plate. The ink is then transferred from the plate to a rubber blanket and ultimately imprinted onto the paper through a process of lithographic pressure, resulting in ink transfer.

Throughout the production process, which encompasses various intermediate stages, the printed material is considered an indirect output.

The most commonly encountered machine for traditional offset printing, particularly in the market, is the Heidelberg printing press, renowned for its four-color capabilities.

Special Edition Printing and Imposition Printing are two different printing methods.

Imposition printing refers to the process of combining multiple files onto a single printing plate. For example, in the case of a two-page spread, it can accommodate eight 16-page layouts or over 100 business card positions. The advantages of imposition printing are its relatively lower cost. However, it has limitations in terms of available printing techniques, subpar color quality, and potential insufficiency in quantity to meet demands.

Special edition printing, on the other hand, involves using separate printing plates for each file. Each file has its dedicated printing plate. The advantages of special edition printing lie in ensuring color accuracy and an ample supply of quantities. However, the price of special edition printing is relatively higher, especially for smaller quantities.

Digital printing is commonly used for printing materials with low print quantities or those requiring special paper. Due to its simplified process and less complexity compared to traditional printing machines, digital printing machines are often chosen when quick printing is needed.